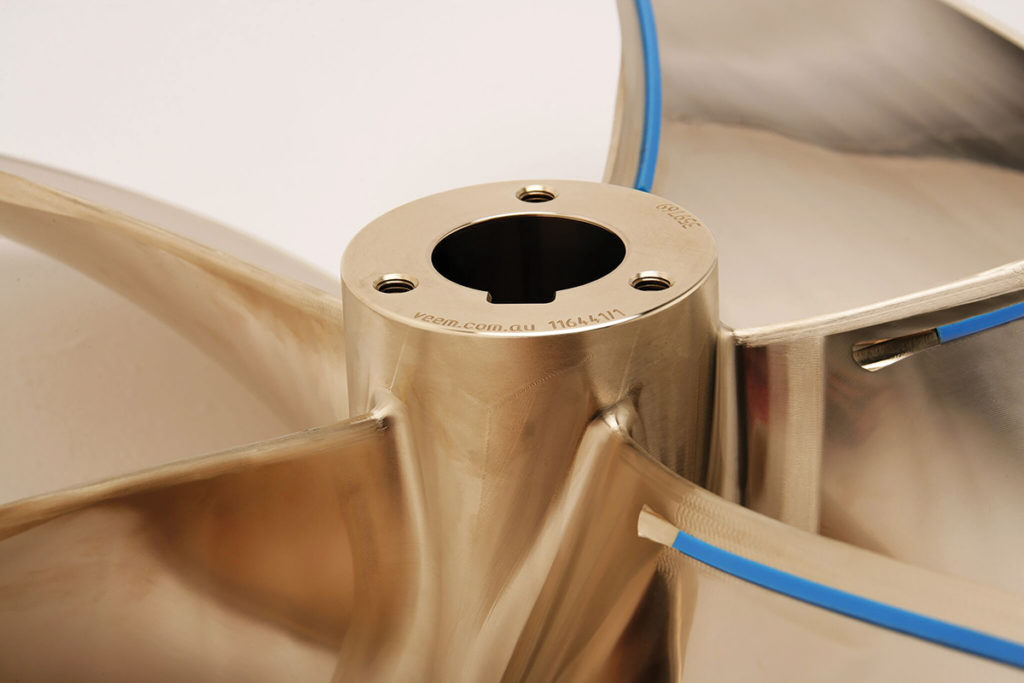

From the earliest days of screw production, propeller manufacturing has relied on the limitations of pattern molding to produce high performance propulsion systems. It was the redefining of this process and other technology innovations that have taken VEEM to the forefront of the marine propulsion industry around the world.

With propellers already achieving speeds up to 50 knots and better back-down performance than any other propeller on the market, VEEM propellers continue to push the boundaries of marine innovation to deliver manufacturing perfection, precise designs, and the highest performing propellers in the world.